Time:2022-12-06 Views:

The pandemic has disrupted global supply chains and logistics pipelines for many other raw materials and manufacturing industries, and companies are finding it a challenge to adequately staff their operations in an environment of tight labor markets. However, chip shortages are still in the headlines, and the general narrative is that the auto industry slashed semiconductor orders at the start of the pandemic in early 2020 — a time when other industrial sectors, such as consumer electronics, ramped up chip orders to meet demand for telecommuting and Growing demand for educational equipment. Chipmakers have allocated capacity to meet these growing industries, and it will take some time to reallocate capacity to meet automotive demand.

While this view is accurate, it is incomplete. The ramifications of semiconductor supply issues are far more far-reaching, and the semiconductor supply-demand imbalance in the auto industry has lasted far longer than many industry watchers initially expected. The solution is not just reallocation of capacity.

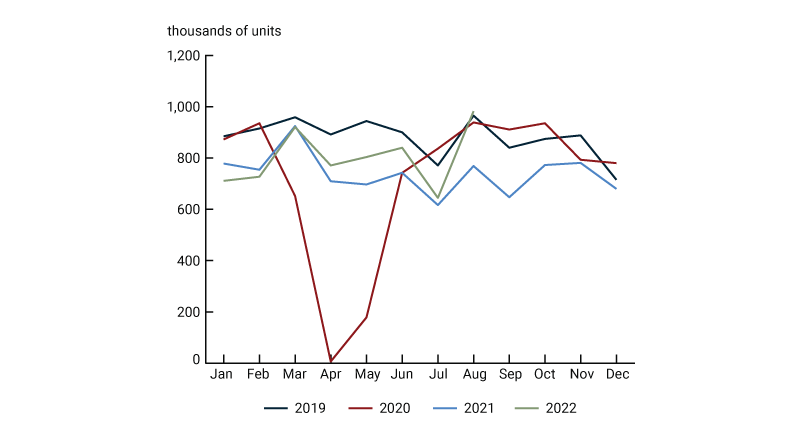

Automakers around the world are still struggling to produce light vehicles at the pre-pandemic pace. Figure 1 shows monthly U.S. light vehicle production from January 2019 to August 2022.

Affected by the epidemic, automobile production fell to a low level from March to June 2020, but in July to October of that year, production rebounded quickly to the "normal" level in 2019. Then, starting in November 2020, supply chain issues began to surface, and production was again below 2019 levels and largely maintained until July 2022. August 2022 marks the first time since December 2020 that U.S. light vehicle production returns to 2019 levels.

Annual U.S. light vehicle production averaged 11.2 million in the five years before the pandemic, hovering at just under 9 million in 2020 and 2021; production is now expected to be just under 10 million by the end of 2022 car. The production shortfall is not just a U.S. problem; disruptions in global supply chains have led to global auto production projected to drop by more than 35 million vehicles in 2020, 2021 and 2022 from pre-pandemic levels.

Together, these factors continue to make it more difficult to supply enough production to meet global semiconductor demand. S&P Global estimates that semiconductor lead times have stretched to as much as four times what they were before the pandemic — meaning chips arriving at factories in 2022 could have been ordered sometime in 2021. While automakers report that semiconductor supplies are starting to normalize, meaning the chips they ordered arrive when they expect them to, the supply-demand imbalance could persist into 2023 and beyond.

Skype:szmyxdz@163.com

Tel: +86-13530718420

Email: szmyxdz@163.com

Company Homepage:en.icmyx.com

Working Hours:Monday To Saturday 00:00-24:00

+86-13530718420

+86-13530718420

Skype:szmyxdz@163.com

E-Mail:szmyxdz@163.com

Company Address:A309-s31604, Rongchao economic and Trade Center, No. 4028, Jintian Road, Fuzhong community, Lianhua street, Futian District, Shenzhen

官方二维码

Links:

Copyright 2022 Shenzhen Meiyu core technology Co., Ltd Telephone:+86-13530718420 Guangdong ICP No. 2022094269-1

Service Hotline

Monday To Saturday 00:00-24:00

Skype

szmyxdz@163.com